Making things by printing them

Manufacturing is an enormous part of the global economy. By some measures, the sector contributes more than $12trn to global output.

There are many ways to manufacture things. Three of the main ones are formative (injection moulding), subtractive (CNC milling), and additive (3D printing).

Injection moulding if the process of injecting a material (e.g. plastic) into a mould to produce many copies. This is useful if you need to make, e.g. a million Lego bricks. The drawback is that it is costly and timely to make the first mould. So, if we just need a few copies of something, injection moulding is not the answer.

CNC milling is the process of cutting pieces away from a block of material (e.g. metal). This is useful if you need to create a few hundred parts of something. The process is highly precise and scales to produce exact replicas. The downsides are that a) it is relatively time-consuming to make each part, b) it requires quite skilled operators and c) there is a lot of wasted material.

3D printing is the process of depositing layers of material on top of other layers until you have a final product. This is extremely useful if you need a custom component at low volume – for example, a prototype of an item. It is also excellent at really complex geometries. However, the process works best at a small scale (e.g. a desktop item). For larger things like machine, aerospace or automotive parts, the process has been too inaccurate and too error-prone. It has also been too time-consuming, with competent operators having to re-run print-job after print-job (with job failure rates for large jobs typically cited at 65%). Every time this happens, the print operator must adjust the job parameters and then rerun the process. It can take weeks.

That is – until now.

Next-generation 3d printing

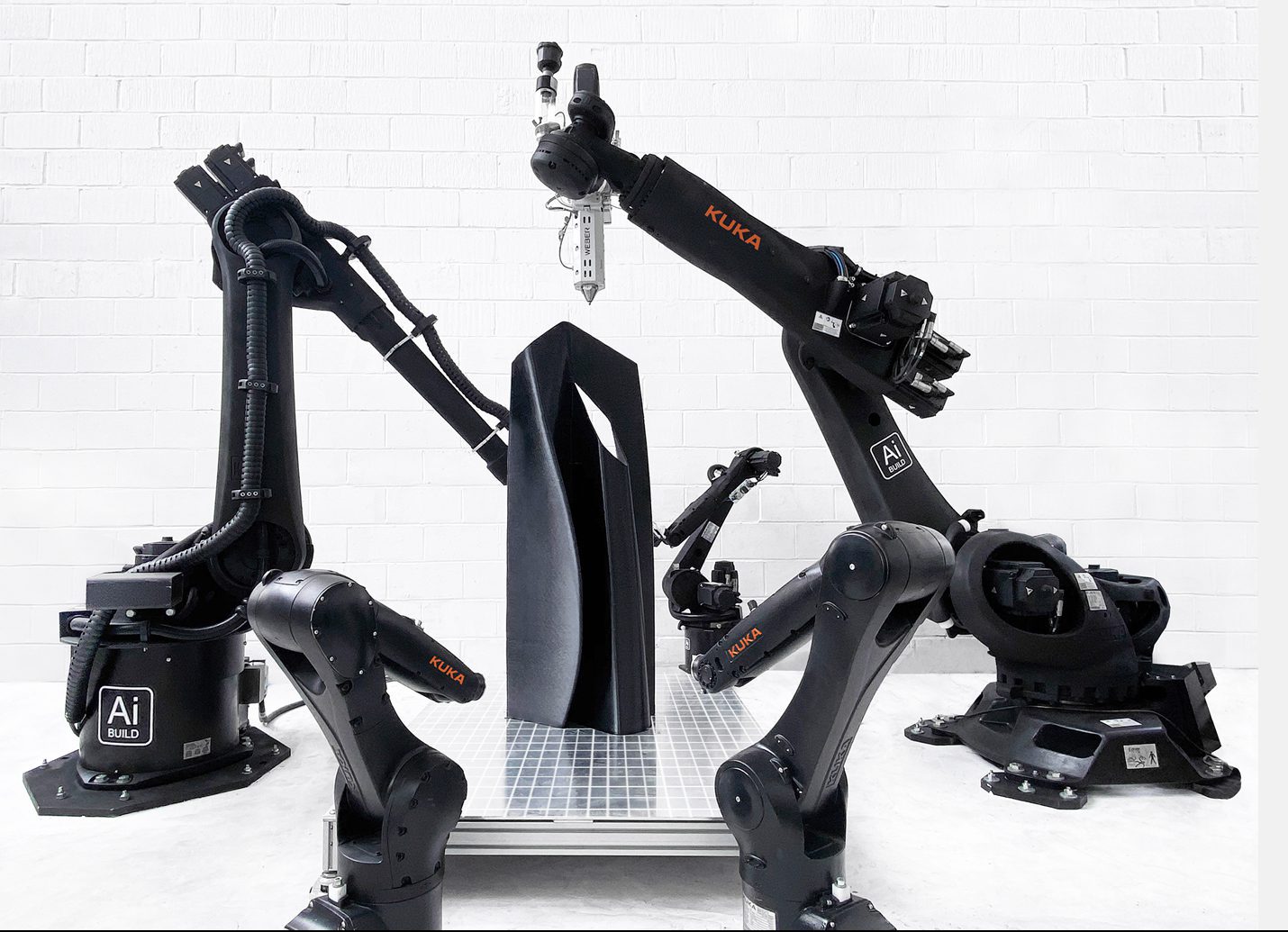

Enter Ai Build – founded in 2017 by Daghan Cam and Michail Desyllas. Over the past three years, the founders have put leading-edge research within generative algorithms, robotics and computer vision to create the Ai Build platform. Their solution automates and accelerates large parts of the 3D printing process. It does this by pre-optimising 3D print jobs and then – once the print is taking place – auto-correcting the many small issues that can happen during a print-job. This way 3D print operators can create much bigger geometries, much faster, and with higher quality.

The technology reduces the human effort required to produce a large 3D printed object by up to 86%. It also opens up 3D printing to much larger components than have been the case in the past. Finally, it reduces material wastage, as it is now possible to create very large objects by using just the necessary amount of material.

When starting out, the Ai Build team found that commercially available 3D printers were too limited in capability to support their ambition for high-quality, large-scale 3D prints. Therefore, they initially made their own hardware, so that they had printers that were sufficiently sophisticated to meet their exacting standards.

As Ai Build is a software company at heart, they have now partnered with equipment manufacturing specialists Weber and Kuka. This means that Ai Build can now focus on perfecting the software platform.

Ai Build is already supporting several large industrial companies with their rapid prototyping needs. We see Ai Build’s technology as having wide application across aerospace, automotive, construction and other manufacturing areas. Team SuperSeed is excited to support Daghan and Michail as they continue on their journey to build a great company in the additive manufacturing space.

This article is published by SuperSeed Ventures LLP which is authorised and regulated by the Financial Conduct Authority. The article does not constitute substantive research or analysis, and should not be construed as an investment recommendation in relation to any publicly traded company. Please note, investments in unlisted early stage companies are illiquid and expose investors to a significant risk of losing all money invested. Please always seek independent financial advice before making investment decisions.